Introduction to Products Developed by Us

TBIS® Series

Bisphenol derivatives

Reflecting the market needs for high functional products, Taoka is developing various bis-phenol derivatives which is called "TBIS®".

TBIS® products is an excellent raw material for optical plastics which require high transparency and heat-resistance.

Especially, Fluorene-type products have a high refractive index and low birefringent due to its "Cardo Structure".

| Chemical name [product name] | Structure | Typical properties, etc. | Stage | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TBIS®-G |  |

|

Commercial | ||||||||||

| CHBP-F |  |

|

Commercial | ||||||||||

| TBIS®-RX |  |

|

Pilot | ||||||||||

| TBIS®-ZP |  |

|

Pilot |

CSCL:Chemical Substances Control Law

[Applications] Raw Monomer or Modifier for Optical Resin or Electronic Materials.

Epoxy delivertives

This product has a high refractive index, transparency and heat-resistance due to it's unique structure containing a fluorene skeleton.

Compared to existing bisphenol fluorene epoxy resins, these compounds have a high refractive index, high solvent solubility, and excellent handling characteristics.

| Name of chemical [product name] | Structure | Typical properties, etc. | Stage | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TBIS®-GG |  |

|

Pilot | ||||||||||

| TBIS®-RXG |  |

|

Laboratory |

[Applications] Electronic Materials (Photoresist, Mounting Agent), Optical Materials, Adhesive, Coating Materials, Laminating Agent, Additives etc.

Acid dianhydride derivative

This product has a high refractive index, transparency and heat-resistance due to it's unique structure containing a fluorene skeleton.

When used as a monomer for polyimide, the workability will be improved due to its superior solvent solubility.

| Name of chemical [product name] | Structure | Typical properties, etc. | Stage | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TBIS®-RXN |  |

|

Laboratory |

[Applications] Raw Material for Polyimide or Polyamide, Curing Aagent for Epoxy Resin, or Urethane.

Episulfide delivertive

The episulfide shows the characteristic of curing at low temperatures.

The cured material is also low in the odor that is unique to sulfur compounds and excels in transparency while also having properties such as a low dielectric characteristic and low water absorbency.

| Name of chemical [product name] | Structure | Typical properties, etc. | Stage | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| TBIS®-AHSP |  |

|

Pilot |

[Applications] Adhesives, Additive of epoxy-resin etc.

Acrylate derivative

TBIS®-ZPC is an acrylic monomer with a fluorene skeleton, and has high solvent solubility while achieving a high refractive index.

It also has excellent storage stability at room temperature and can be stably handled without crystallizing in solution.

| Name of chemical [product name] | Structure | Typical properties, etc. | Stage | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| TBIS®-ZPC |  |

|

Pilot |

[Applications] Electronic Materials, Optical Materials, Additives etc.

* We also offer examination of synthesis for various diols, diamines, acid dianhydrides, epoxy, acrylate etc.

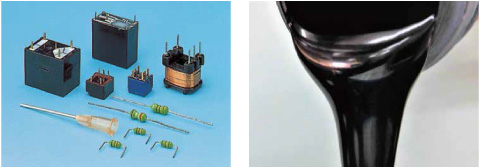

LCP adhesive AH7042X

Excellent heat resistance, low outgassing, and improved adhesive property at high temperatures

Characteristics

- Excels in heat resistance and high temperature durability, and can be utilized in LCP relay sealing

- No need for the mixture of the main agent and curing agent, which is essential for two-component epoxy

- Generates little gas during the curing process (low outgassing)

- Can be adjusted to the viscosity and degree of dripping needed to suit the application

| Grade | High heat resistance | ||||

|---|---|---|---|---|---|

| New product | Developed product | Existing product | |||

| Name of product | AH7042X | AH7042X-5 | AH8042KL | AH1032K | |

| Standard curing conditions | 110℃×60 minutes | 100℃×60 minutes | |||

| Viscosity(Pa・s/25℃) | 35 | 32 | 35 | 30 | |

| Thixotropic index(25℃) | 2 | 2 | 1.5 | 2 | |

| Tg(℃)[TMA] | 129 | 134 | 119 | 113 | |

| LCP TSS (N/mm2) | Initial | 10 | 10 | 9 | 8 |

| After heat aging | 7 | 7 | 7 | 3 | |

*LCP manufactured by Company S used. After heat aging ... Measured after exposure at 270℃×10 minutes.

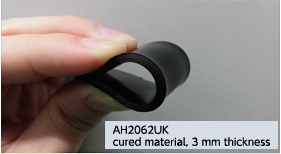

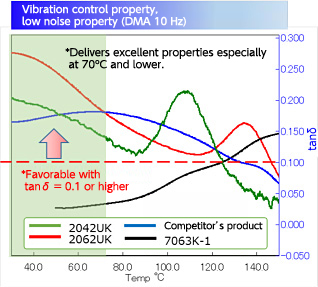

Flexible AH2062UX Developed product

Flexible grade, excellent damping, low noise

Characteristics and physical properties

| Name of product | 2042UK | 2062UK | Competitor’s product | |

|---|---|---|---|---|

| High flexibility | High adhesion | |||

| Viscosity(Pa・s/25℃) | 33 | 58 | 46 | |

| Thixotropic index(25℃) | 1.7 | 1.7 | 1.7 | |

| Gel time(min/100℃) | 3 | 2 | >100 | |

| Physical properties of cured material | Hardness(25℃) | A 64 | A 87 | D 40 |

| tanδ(*1) | 0.21 | 0.28 | 0.16 | |

| E'(MPA)(*1) | 6 | 93 | 81 | |

| Tensile-shear adhesion strength (N/mm2) | Standard curing conditions | 120℃×60 minutes | 120℃×60 minutes | 110℃×120 minutes |

| Steel | 5 | 10 | 13 | |

| PBT3300 | 2 | 4 | 3 | |

| T-type peeling adhesion strength (N/mm2) | Steel | - | 2 | 1 |

| Aluminum | - | 2 | 1 | |

(*1) DMA 30℃ 10Hz

TACKIROL® 201 (alkylphenol-formaldehyde resin)

TACKIROL® 201 is known as a resin crosslinking agent with excellent performance.

TACKIROL201L30

- Advantages of liquefaction

- Improvement in the dispersibility in polymers

- Blocking resistance

- Prevention of dust scattering