Technical Information (Contracted Synthesis)

About Contracting

We have been a pioneer in the development of instant adhesives, pharmaceutical and agricultural chemical intermediates, photographic chemical intermediates, inkjet inks, polarizing film dyes, and raw materials for optical resins, contributing to the development of cutting-edge fields such as information and communications.

Utilizing our technology and know-how, we are capable of manufacturing on a scale ranging from tens of kilograms to tonnes, and we will provide products that meet your needs under strict quality control.

- [1] Request/consultation

- We accept requests at any time through the visits of our employees to your company, visits of the customers to our company, phone calls, use of inquiry forms, etc. Please feel free to contact us if you have a problem that needs to be solved.

- [2] Technical meeting

- We will check the presence of the manufacturing process and synthesis route development, etc. We will conclude a non-disclosure agreement as necessary, and also make proposals based on our company’s know-how.

- [3] Presentation of a quotation

- We will select the facilities and check the synthesis process based on the technical information that is disclosed. We can select the industrial manufacturing method based on the technology we own and present the estimated price calculated on paper.

- [4] Laboratory examination/quality confirmation

- Once our customer is satisfied with the quotation we presented, we will start the laboratory examination at our company. We will submit samples obtained from the examination and ask the customer to check if they meet the quality they require. We will continue the exchanges including proposal of the synthesis routes from our company and technical details to try to achieve the quality and costs that suit the customer’s demand.

- [5] Scale-up examination

- We will present the quotation again based on the laboratory examination results. When the customer is satisfied with the price, we will start scale-up production for commercial production and try to establish the mass production formula.

- [6] Commercial production

- We will conduct stable and continuous production of the products of better quality with thorough process control.

Flexible response ranging from the cultivation of new synthesis routes to the establishment of industrial manufacturing methods and commercial production

Technologies We Own

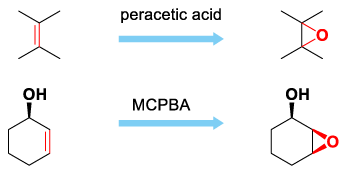

Oxidation reaction

TAOKA owns facilities to produce peroxides, and has a substantial track record in their handling. We also own a peracetic acid manufacturing technique.

· Reaction for C-C unsaturated bond

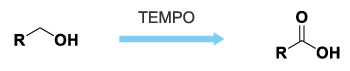

· Reaction of Primary Alcohols (TEMPO Oxidation)

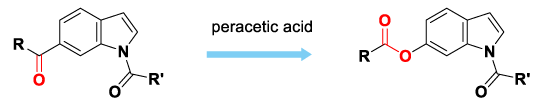

· Reaction for carbonyl(Baeyer-Villiger Oxidation)

Reduction reaction

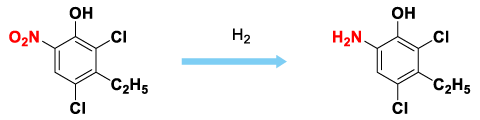

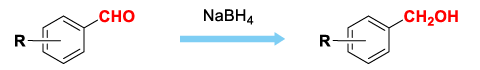

A reduction reaction is an extremely important reaction in synthesizing various organic compounds. TAOKA has a substantial track record in industrialization, including the conversion of the nitro group into the amino group by hydrogenation reaction, and a reaction to reduce the carbonyl group using borohydrides.

· Hydrogenation reaction

· Borohydride reduction

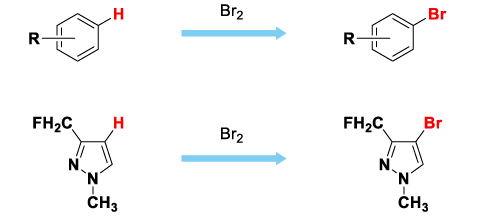

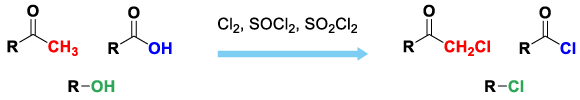

Halogenation reaction

TAOKA has a substantial track record in successfully achieving the industrialization of numerous processes that include halogenation reactions using thionyl chloride, sulfuryl chloride, bromine, etc. For bromine, in particular, we own a tank at the company.

· Bromination reaction

· Chlorination reaction

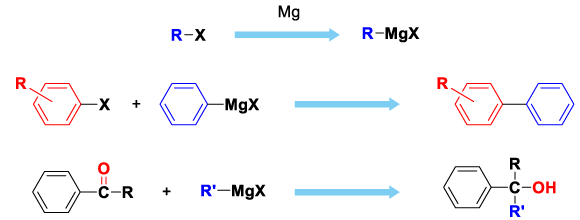

Grignard reaction

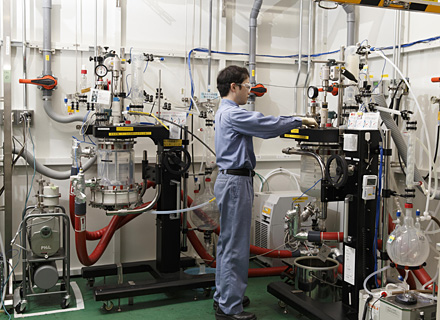

The reactions to form carbon-carbon bonds are extremely important reactions in the synthesis of various different chemicals. The Grignard reaction is one of the most typical of such reactions. TAOKA has the facilities and know-how to conduct a Grignard reaction on a scale of 10,000L, and has successfully industrialized various processes.

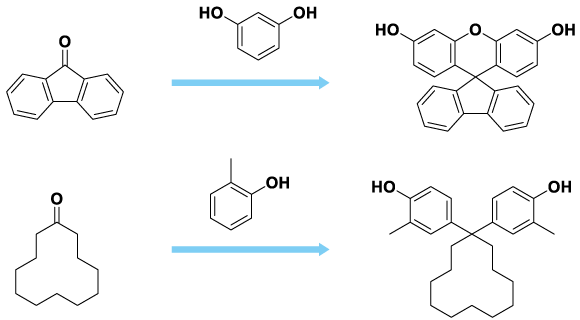

Dehydration condensation reaction

TAOKA implements the development and production of various bisphenol derivatives to meet the needs for high performance and high function substances that are growing in recent years, and has a substantial track record of conducting reactions between phenol derivatives and carbonyl compounds.

Reaction using NaH (water-sensitive reaction)

We conduct reactions using NaH in the scale of 10,000L.

Other manufacturing processes and derivatives TAOKA has experience in (examples)

- · Pyrazole ring synthesis

- · Friedel-Crafts reaction

- · Nitration reaction

- · Diazotization reaction

- · Indolization reaction

- · Esterification reaction

- · Alkylation reaction

- · Cyanation reaction

- · Crystallization control process

Facilities We Own

Outline of the facilities we own

We have various facilities available and are capable of conducting from low temperature (0℃) to high temperature reactions (200℃).

| Equipment | Material | Volume | |

|---|---|---|---|

| Reaction | Reactor | Glass-lined | 100 ℓ 〜 20,000 ℓ |

| Stainless steel | 1,000 ℓ 〜 20,000 ℓ | ||

| HASTELLOY B | 500 ℓ | ||

| Autoclave (up to 0.8 Mpa) | Glass-lined | 100 ℓ 〜 15,000 ℓ | |

| Distillation | Simple distillation still | - | - |

| Rectification column with theoretical plate number 5 to 15 | Stainless steel | ||

| Filteration | Centrifugal filter | Hastelloy | 48,60 inch |

| Stainless steel | 48,60 inch | ||

| Pressure filter | Glass-lined | 0.5m2~6m2 | |

| Stainless steel | 0.5m2~6m2 | ||

| Drying | Nauta dryer | Stainless steel | 3,000 ℓ 〜 8,000 ℓ |

| Conical dryer | Glass-lined | 800 ℓ~3,000 ℓ |

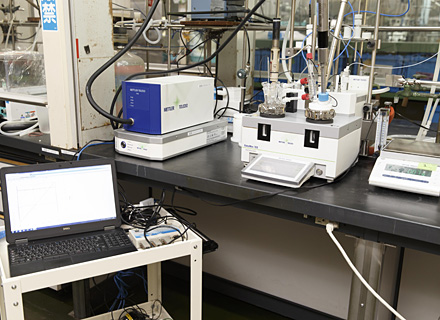

Outline of analytical instruments we own

We have various analytical instruments available while also establishing an assurance system for high product quality.

| General analytical instruments | HPLC, GC, melting point, spectrophotometer, moisture meter, colorimeter, microscope, automatic titrator etc. |

|---|---|

| Trace metal analysis | ICP-MS, ICP-emission |

Research System

Precision Chemical Group

Based on the advanced organic synthesis techniques, crystallization control techniques and purification techniques we accumulated in the pharmaceutical/agricultural chemical intermediate business, we are working on the development of characteristic and proprietary compounds that draw out the functions and performance demanded by the users. We also work on the development of materials in leading-edge fields with incorporation of the latest techniques through exchanges with universities and research institutes.

Primary research themes

Development of special monomers

We develop special raw materials for resins (monomers/polymers) that can be used in electronic material fields and high function components.

We offer the “TBIS®” Series. Fluorene-based compounds in particular deliver characteristics such as high refractive index and low birefringence due to the inclusion of the cardo structure.

In addition, episulfide resins which show characteristics to cure at low temperatures deliver properties such as a low dielectric characteristic and low water absorbency, while also having a low sulfur odor and forming compounds that excel in transparency.

Fine organic synthesis of pharmaceutical and agricultural chemical intermediates

We conduct the development of manufacturing methods for pharmaceutical substances and intermediates of medicines and agricultural chemicals to meet the needs of our customers while utilizing our process development capability we have accumulated.

Functional Material Group

We work on improving the functions and expanding the applications of functional materials (adhesives, rubber additives, etc.) and functional resins (phenol resins, resins for paper processing, etc.) through full use of the polymer synthesis techniques and composition techniques we have accumulated over many years. We also promote the development of functional products that support the leading-edge fields by fusing a variety of techniques in the existing businesses and creating new functions.

Our group promotes developments in coordination with overseas bases in response to the globalization of our business.

Primary research themes

Cyanoacrylate-based adhesives

In addition to our pursuit for quick curing, which is the characteristic of instant adhesives, we work on the development of new products equipped with new properties such as high durability and high strength.

Epoxy resin-based adhesives

We work on the development of high function products with the addition of new properties such as flexibility, low noise and vibration control, as well as those which provide the adhesion of new materials such as LCP and composite materials, with the main focus on electrical material applications.

Phenol resins

We mainly develop high function rubber additives to provide the development of new products such as dynamic crosslinking agents for TPV.

Water-soluble polymers

We work on the development of various water-soluble polymers, mainly as resins for paper processing.

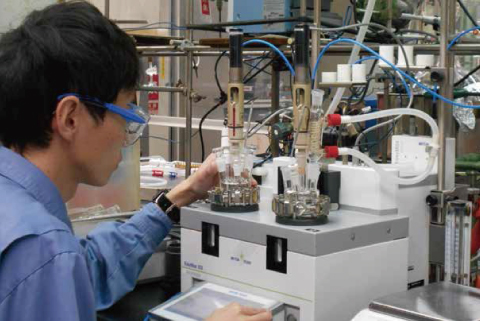

Analysis/Industrialization Group

We work on the development of specialized techniques that support production, such as process development for new products, improvement of existing processes, development of analytical methods in concurrence with industrialization, and introduction of the latest analytical technique, by combining industrialization research and analytical research.

We also work on contracted synthesis which also involves process development with full utilization of our techniques and the know-how we have accumulated in the past.

Primary research themes

Process development

We work on process development based on safety and disaster prevention evaluation with DCS, TG-DTA, reaction heat measurement system etc.

We also work while assuming the plant scale and using chemical engineering analysis as the basis from the process development stage.

Analysis and physical property evaluation

- · Matters related to structural analysis

- We pursue robustness of quality and productivity, while analyzing the structure including impurities through the full use of structural analysis devices such as GC-MS, LC (TOF)-MS, NMR and FT-IR, and conducting quick process development with feedback being given about the process development. We also work while assuming the plant scale and using chemical engineering analysis as the basis from the process development stage.

- · Matters related to physical property analysis

- We actively work on the development of processes that satisfy customer quality requirements by fusing the process development examination and results from the physical property measurement devices such as FBRM, PVM, TMA and DMA.

Quality Assurance

Both of our plants at Yodogawa and Harima have acquired ISO9001 certification to reinforce our quality assurance system and improve the reliability.