Plasticizers

Plasticizers add improved performance to various plastic resins and synthetic rubbers.

They are used in various different applications such as films for food packaging, flooring materials, shoes, hoses, inks, rubber gloves, and food containers that are familiar in our daily lives.

TAOKA offers a wide range of products with the main focus on such plasticizers.

A plasticizer refers to a substance which is added to a certain material to add flexibility and easy processing. Plasticizers are mostly used to increase the elasticity of the plastic.

It consists of ester moiety, which are synthesized from carboxylic acid and alcohol units.

TAOKA products, contribute to create a comfortable life by using well established long historical esterification technology background.

| For films for food packaging and toys | DINA、610A、ATBC、DBS | |

|---|---|---|

| For synthetic rubbers | DOS、SR-86A 、SR-618、DODN | |

| For lubricants | DINA、DIDA、DOS、DTDA | |

| Other secondary plasticizers | DOA、ATBC、DI4A、DOZ、DOM | |

| Primary plasticizers (general-purpose type) | DOP、DINP、DBP |

Plasticizer for bio-degradable resin

Development

productBPC-110

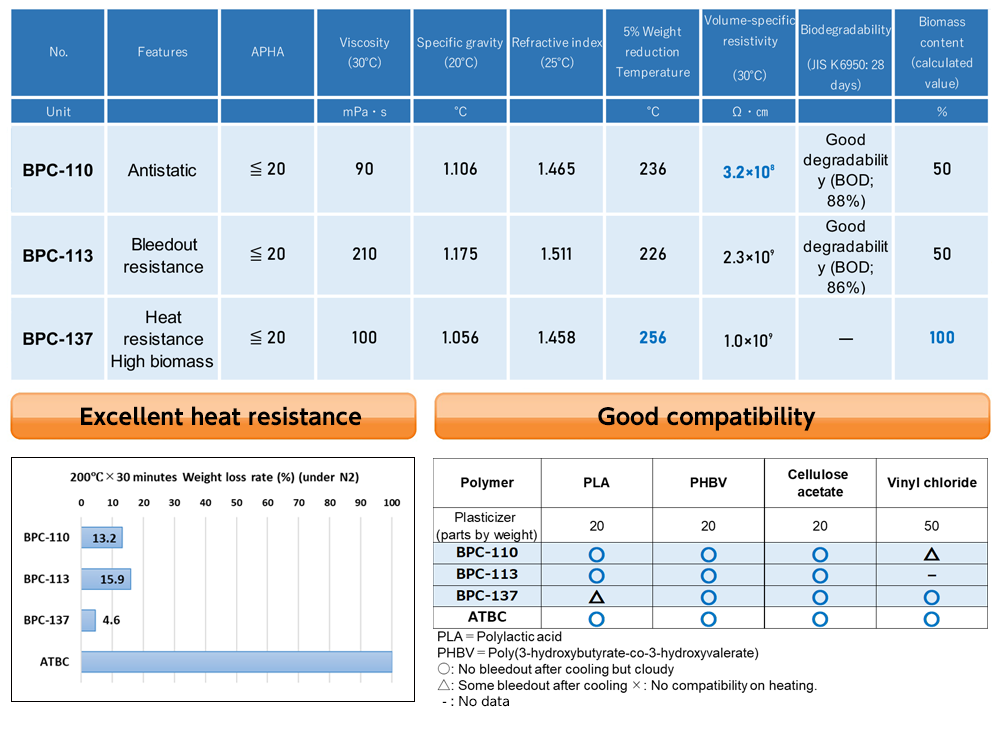

TAOKA Chemical developed new ester type biodegradable plasticizer, BPC-110 series, which can be used for biodegradable polymers such as polylactide plastics (PLA).

- Biodegradable plasticizer BPC-110 series

- BPC-110 series has the following characteristics.

- Excellent compatibility with biodegradable plastics

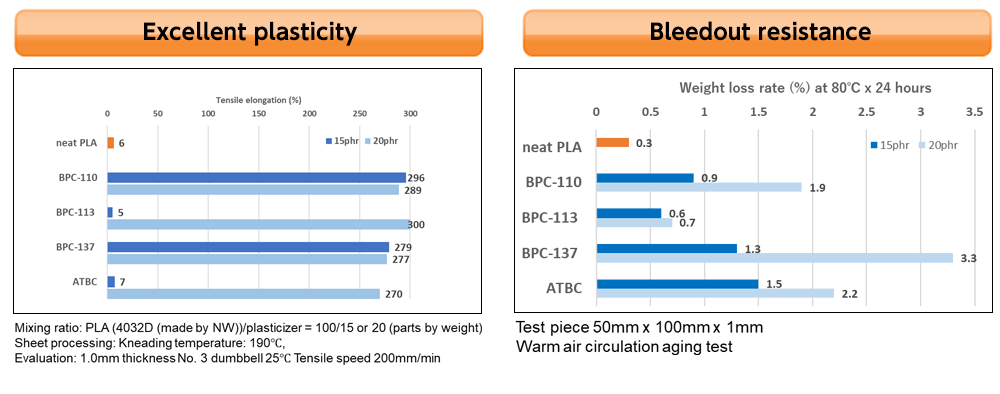

- Good plasticity, high transparency and impact resistance for PLA

- Excellent bleed resistance under high temperature and high humidity

- Its low volume resistivity provides anti-static performance to PLA

- Good biodegradability (88% by BOD test)

FEATURES

Effect of addition to PLA

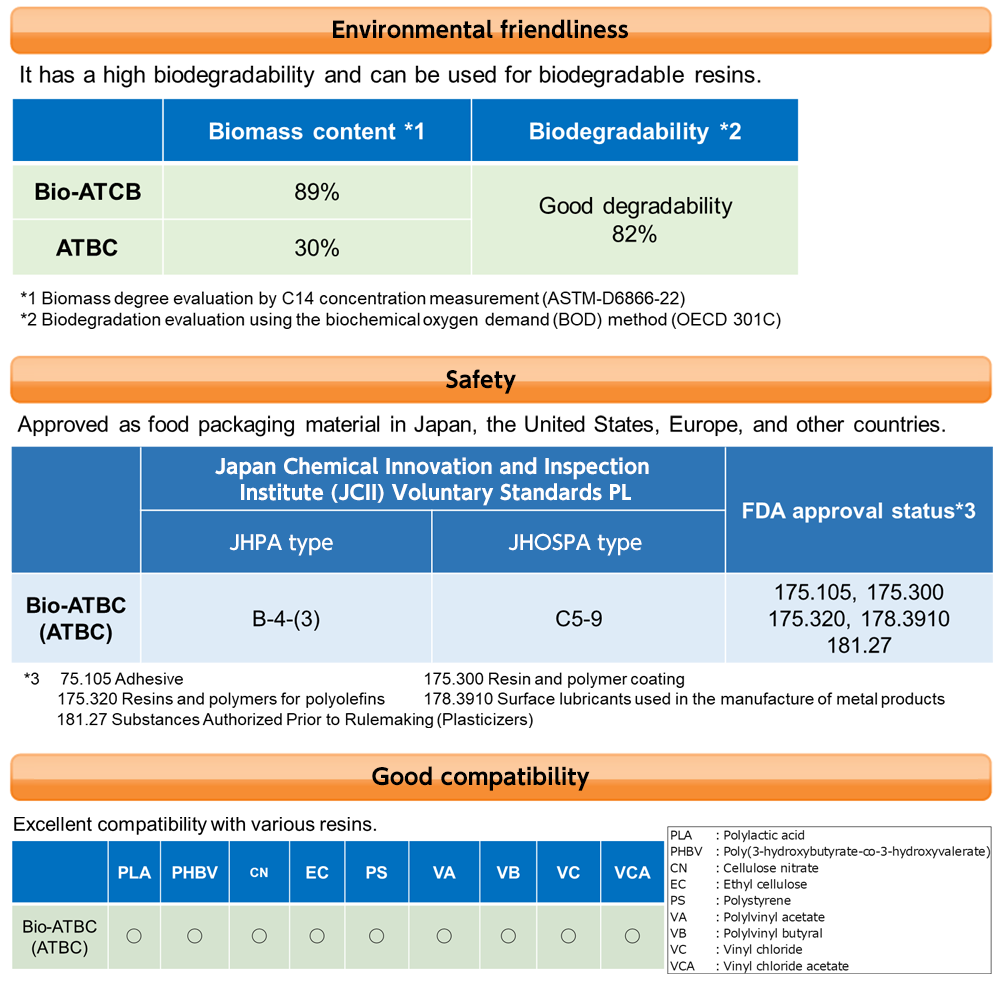

Plasticizer with high biomass content

Development

productBio-ATBC

FEATURES

Biodegradable plasticizer with high biomass content.

- Applications:

- Raw food packaging films, children's toys, erasers, fishing lures (worms), paints, inks, etc.